In the refractory industry, it is well known that steel fiber castables are prepared by adding stainless steel heat-resistant fibers. In addition to the conventional high-temperature abrasion resistance, the product has a certain amount of heat-resistant stainless steel fiber added to its ingredients to prevent the difference between the aggregate and the matrix in the material at high temperatures.

Characteristics of Steel Fiber Castable

- (1) Steel fiber strengthens the tensile and flexural strength of refractory castables.

- (2) Castables of the same material. Castables reinforced with steel fiber will drop corners after 19 cycles of water cooling at 1100°C, while castables without steel fiber reinforcement will drop corners after 14 cycles. Excellent, which proves that steel fiber reinforcement can improve the thermal shock resistance of the castable.

- (3) Steel fiber reinforced refractory castables can still bear the load even after cracking, thereby improving the fracture resistance of the castable and increasing the strength of the refractory castable.

The Main Application of Steel Fiber Castable

Which furnace parts are suitable for steel fiber refractory castables? Refractory manufacturers have compiled the following furnace parts for your reference.

Steel fiber reinforced castable is made of special grade bauxite clinker as aggregate, and high-quality bauxite clinker and corundum fine powder as matrix. It is made of superfine powder and other composite materials as binders and additives, plus stainless steel heat-resistant fibers. At the same time, due to the addition of steel fibers, the overall strength of the furnace wall is greatly enhanced after the material is poured. Steel fiber castables are mainly used in the following areas:

- The inner lining of various thermal equipment.

- The flue, heat insulation in the large-diameter metal chimney.

- Industrial boiler lining, the effect is more obvious when used on the top of the furnace.

- Low-temperature air (≤1200℃) heat insulation in the pipeline.

- KT-J anti-carburizing fiber castable is used for muffle-free carburizing furnace lining.

- Various general and special-shaped prefabs can meet the special application requirements of users.

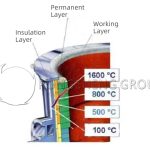

- Backing insulation layer (including furnace wall and furnace roof) with a variety of low-temperature furnace interface temperature ≤1050℃.

- In industrial furnaces with flat flame burners, the roof of the furnace is sealed and insulated, and the sealing effect is better than any other materials.

- Resistance furnace lining with task temperature ≤1200℃, the electric heating element can be exposed, and it can also be made into an embedded structure.

- There is no mechanical vibration in the task, and the furnace lining with large temperature changes is especially suitable. Such as bell-type furnace, removable aluminum melting furnace cover, etc.

- HS-J ultra-low temperature refractory fiber castable, ML-J polycrystalline mullite fiber castable, L80-J alumina fiber castable. It can be used for the lining of industrial furnaces with a task temperature of 1300-1450°C.

- All kinds of fuel furnace lining with task temperature ≤ 1250℃, including furnace wall and roof. Different types of refractory fiber castables are used to make composite furnace linings, with fluctuating structure, economical and reasonable, and convenient construction.

Performance and Formula of Steel Fiber Refractory Castable

The heat-resistant steel fiber used for common steel fiber refractory castables should be selected according to the use conditions of thermal equipment, and the appropriate amount should be determined. The preparation process as follows. First, weigh the refractory aggregates, powders, binders, and additives, dry mix 1mim, and then mix with water and wet, and evenly sprinkle the steel fibers into the material without forming agglomerates. After mixing for 1 min, the material can be discharged. The total mixing time shall not be less than 5 minutes. When vibrating rods are used for molding, the vibration direction should be staggered, so that the steel fiber distribution direction is reasonable and performance can be improved.

| Items | 1 | 2 | 3 | 4 | 5 | |

| Chemical Composition / % | Al2O3 | 65 | 90 | 74 | 68 | 84 |

| MgO | – | 4.4 | – | – | – | |

| CaO | 1.4 | 3.2 | 1.5 | 1.2 | 2.0 | |

| Compressive Strength / MPa | 1d | 10 | – | 15 | 14 | – |

| 110℃ | 14 | 69 | 40 | 49 | 150 | |

| 1000℃ | 40 | – | 70 | 74 | – | |

| 1500℃ | 43 | 91 | 76 | 80 | 150 | |

| Flexural Strength / MPa | 110℃ | 6 | 11 | 5 | 6 | – |

| 1000℃ | 12 | – | 11 | 12 | 19 | |

| 1500℃ | 13 | 21 | 13 | 13 | 23 | |

| High-Temperature Flexural Strength / MPa | 1400℃ | 2.1 | 9.6 | 2.4 | 2.8 | – |

| Line Changes after Burning | 1000℃ | -0.10 | – | +0.08 | -0.02 | ±0.1 |

| 1500℃ | +0.22 | +0.62 | +0.30 | +0.10 | ||

| Refractoriness / ℃ | 1770 | 1830 | >1790 | >1790 | >1790 | |

| Bulk Density / g/cm3 | 2.38 | 3.26 | 2.60 | 2.62 | 2.90 | |

The above table shows the performance of a certain steel fiber refractory castable.

No. 1 is high-strength clay combined with refractory castable. The refractory aggregate and powder are made of third-grade and first-grade bauxite clinker respectively. In order to improve the performance of the matrix, fused brown corundum powder is added, and active SiO2 ultrafine powder and additives are added. Use CA-50 cement as coagulant.

No. 2 is fused calcium aluminate cement aluminum-magnesium refractory castable, dense fused corundum is aggregate, alumina and high-purity sintered magnesia powder are used as refractory powder, and superfine powder and compound additives are added at the same time.

No. 3 and No. 4 are low cement bauxite-mullite refractory castables, and refractory aggregates are made of first-grade bauxite clinker and mullite. The refractory powder is super-grade bauxite clinker powder or corundum powder, the binder is CA-70 cement, and superfine powder and composite admixtures are added at the same time.

No. 5 is a low cement, special alumina corundum refractory castable with a small number of additives. This type of high-quality refractory castable is used at higher temperatures, so the grade 330 heat-resistant steel fiber is selected. The equivalent diameter is 0.5mm, the length is 20mm, and the dosage is 2%. The water consumption is 6% ~7%. According to the selected mixing ratio, various raw materials are weighed and formed after kneading. After molding, it should be naturally cured and no water should be sprayed. After 24 hours of curing, remove the mold and continue natural curing for another 48 hours to check the performance.

With the development of unshaped refractory castables, prefabricated products of steel fiber refractory castables are also used in kiln parts. The information on this will be sorted out before sharing it with you.