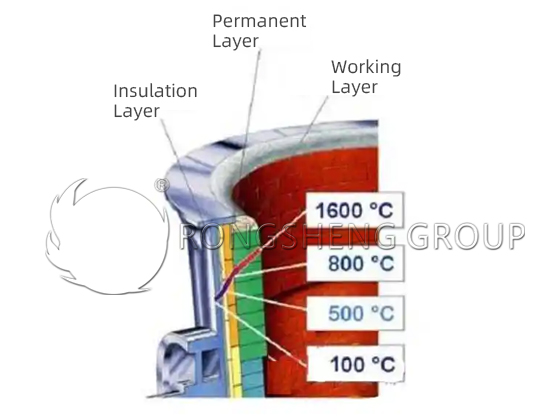

Al2O3-SiC-C castables have excellent thermal shock resistance and slag resistance, and are widely used in blast furnace tapping channels, ladle linings, and slag lines of mixed iron furnaces. Al2O3-SiC-C (hereinafter referred to as ASC) castables mostly use ultra-low cement bonding systems composed of alumina micropowder, silica micropowder, and a small amount of calcium aluminate cement. Compared with ultra-low cement bonding, calcium aluminate cement bonding without silica micropowder and cement-free bonding have the characteristics of high purity and small amount of liquid phase generated at high temperature. Therefore, it has excellent high-temperature mechanical properties and slag resistance.

Bonding Methods of ASC Castables

For a long time, people have been accustomed to the ultra-low cement bonding method and the application of silica powder in ASC castables. Therefore, there are few applications and research on calcium aluminate cement bonded ASC castables without silica powder. Common cement-free bonding methods for castables mainly include silica powder agglomeration bonding, hydrated alumina bonding and sol bonding. The shortcomings of silica powder agglomeration bonding are low body strength, hydrated alumina bonding body strength, poor burst resistance, etc., which make these two bonding methods less used in ASC castables. In recent years, with the development of silica sol bonded castable technology, a small amount of silica sol bonded ASC castables have appeared on the market. With the development of alumina sol bonding system, alumina sol bonded ASC castables that replace hydrated alumina may have better performance.

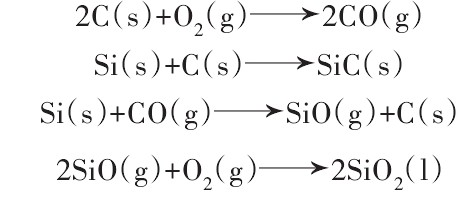

It is well known that the good thermal conductivity of silicon carbide and carbon in ASC castables gives the material better thermal shock resistance, and the non-wettability of carbon and slag gives the material better slag resistance. Carbon plays a key role in the structure and performance of ASC castables. However, carbon is easily oxidized at high temperatures, which deteriorates the material structure and performance. Carbon can be oxidized by oxygen in the atmosphere and by the material’s own oxide components, such as SiO2. When SiO2 and carbon coexist, the generation and escape of SiO2 gas at high temperatures will consume the carbon in the material, increase the porosity of the material, and thus deteriorate the performance of the material. It can be seen that as far as ASC castables are concerned, the SiO2 component may have an adverse effect on its performance. Based on the above analysis, this work studied the changes in phase composition and chemical composition of four common bonding methods of ASC castables: silica sol, silica-free micropowder cement, hydrated alumina and ultra-low cement, and conducted thermodynamic analysis.

Thermodynamic Properties of Al2O3-SiC-C Castables

(1) After calcination at 1350℃, the mass of all samples with different bonding methods increased significantly. Compared with the samples calcined at 1350℃, the mass change rate of the samples calcined at 1500℃ decreased significantly except for the pure calcium aluminate cement bonding method without silica powder.

(2) Thermodynamic analysis showed that under the carbon coexistence calcination conditions in the Si-O-C-N system, SiO2 is a stable phase when the temperature is below 1431℃, and SiC is a stable phase when the temperature is above 1431℃. Si and SiC in Al2O3-SiC-C castables are oxidized by CO at low temperatures, which increases the C and SiO2 contents in the castables.

(3) Under the carbon coexistence calcination conditions, the stability order of SiO2-containing compounds is: cristobalite < mullite < anorthite. Under the condition of 1500℃ carbonization, both cristobalite and mullite can be reduced by C, while anorthite can only be reduced by C when there is enough Al2O3 around it. When the temperature does not exceed 1550℃, Si can prevent C from being oxidized by SiO2-containing compounds, and SiC can only prevent C from being oxidized when the temperature is lower than 1431℃.

(4) When the SiO2 content in the material is high, more SiO gas will escape from the reaction, which will lead to a reduction in sample mass and unstable structure. Considering that silica can promote the formation of SiC, the amount of silica powder added to ASC castables should be minimized.

Low Cement SiC Refractory Castable

Low cement SiC refractory castable is characterized by low linear expansion coefficient, high thermal conductivity, high strength and good wear resistance. It has been applied in thermal equipment such as power generation boilers, non-ferrous metallurgical furnaces and incinerators, and the use effect is good. Low cement SiC refractory castable uses silicon carbide with SiC greater than 97% as refractory aggregate and powder, adds SiO2 ultrafine powder and metal silicon antioxidant, uses CA-70 cement as binder and adds polyphosphate water reducer. The main properties of this material are SiC of 85%, 110℃ drying bulk density, pressure resistance and flexural strength are 2.5g/cm3, 45MPa and 9MPa respectively. After burning at 1000℃, the linear change, pressure resistance and flexural strength are -0.2%, 107MPa and 24MPa respectively. After firing at 1450℃, the linear change, compressive strength and flexural strength are +0.3%, 130MPa and 54MPa respectively, and the thermal conductivity at 400℃ is 12.2W/(m·K).

Rongsheng Refractory Castable Manufacturer

Rongsheng Refractory Castable Manufacturer, advanced environmentally friendly fully automatic amorphous refractory production line, specializes in providing refractory products for high-temperature industrial furnace linings. Rongsheng’s refractory products have been sold to more than 120 countries and regions around the world, including South Africa, Chile, Egypt, Colombia, Uzbekistan, Italy, Indonesia, Ukraine, Hungary, Spain, Kenya, Syria, Zambia, Oman, Venezuela, India, Peru, the United States, Ethiopia, Iran, Iraq, Israel, etc. If you need to buy high-quality silicon carbide refractory castables, low-cement silicon carbide refractory castables, Al2O3-SiC-C castables, please contact Rongsheng manufacturers. Get free samples and quotes.