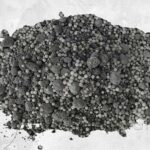

Many people may wonder whether adding silicon carbide to refractory castables can increase strength? It is well known that adding silicon carbide to refractory castables can increase the strength of the castables. However, the addition of different proportions has different effects on the performance of refractory castables. What are the effects of adding silicon carbide on Refractory Castables Properties? Refractory manufacturers have come to the following conclusions by analyzing experimental data.

What Effects Does the Addition of Silicon Carbide have on the Refractory Castables Properties?

The proportion of silicon carbide added in the refractory castable is too high, which will affect the strength of the castable at medium and low temperatures. Early mulliteification is prone to occur, and the stomata will be relatively reduced. However, the compressive strength of refractory castables increases at high temperatures.

If too little or no silicon carbide is added to the refractory castable, the strength of the castable will decrease by 25%. The current silicon carbide castable is actually a high-strength high-aluminum castable with few silicon carbides. Therefore, the high aluminum castable strength maintained by the castable without silicon carbide.

The addition of silicon carbide to the refractory castable is too low, then it will not play the role of increasing the compressive strength of wear resistance. At this time, judging from its performance, it is just a high-aluminum castable. However, under certain conditions of severe lining erosion, it is still necessary to add silicon carbide to the high-aluminum castable to change the properties of the castable. In order to improve the thermal shock stability and wear resistance coefficient of the refractory castable, the service life of the lining is longer.

Of course, excessive addition of silicon carbide in the refractory castable will react with silicon dioxide, and too little addition will have no effect. How to balance it? Generally, when the furnace is not severely eroded and the erosion is not severe, add 6% silicon carbide to the refractory castable. It is the best balance ratio to use in the strength of semi-finished products or high-temperature areas.

The effect of the amount of silicon carbide added on the apparent porosity of the castable. With the increase in the amount of silicon carbide added, the apparent porosity gradually decreases after heat treatment at 1400 ℃. This shows that as the liquid SiO2 on the surface of silicon carbide increases, more closed pores are formed. At high temperatures, the apparent pores are continuously reduced, and the degree of densification will increase.

The effect of the amount of silicon carbide added on the linear change rate of refractory castables. With the increase of the amount of silicon carbide powder added, the linear rate of heat treatment at 1400℃ gradually decreases. The main reason is that the surface of silicon carbide is oxidized into a liquid SiO2 film at high temperature, showing a trend of increasing volume. This reaction occurs slowly from the outside to the inside, and correspondingly offsets the shrinkage of the substrate. In addition, 1100-1350 ℃ is also the formation stage of mullite. The outer layer of silicon carbide is oxidized to form liquid SiO2, which reacts with alumina powder to form staggered, acicular mullite crystal phases. Accompanied by the larger volume expansion, it compensates for part of the line shrinkage.

The Influence of the Amount of Silicon Carbide Added on the Refractory Castables Properties

The effect of the amount of silicon carbide added on the high-temperature flexural strength of refractory castables. The high-temperature flexural strength of the refractory castable after firing at 1400°C, with the increase of the silicon carbide content, the high-temperature flexural strength is significantly enhanced, and it is much higher than that of the castable without silicon carbide. This is a very significant feature brought by silicon carbide.

When the addition amount of silicon carbide is above 5%, it has good alkali resistance. With the increase of the added amount, the corresponding corrosion resistance and thermal shock resistance can be improved. However, adding a small amount of silicon carbide to the corundum-mullite castable has an effect on the physical properties at room temperature, high-temperature flexural strength, and microstructure. At the same time, trace silicon carbide will not significantly increase the thermal conductivity and heat loss of the castable.

In summary, increasing the content of silicon carbide from 1% to 5% can increase the strength of the refractory castable after heat treatment at 110-1500°C. However, increasing the content of silicon carbide from 5% to 9% will affect the strength of the castable after heat treatment at 1100°C. After the addition of silicon carbide, the wear resistance of the castable is hardly improved after the 110°C treatment; after the 1100°C treatment, the wear resistance of the castable with the silicon carbide content of 1% to 5% is slightly improved. However, the wear resistance of castables with SiC content of 5%-9% is worse.

Rongsheng Refractory Castables Manufacturer

The production of refractory castables does not go through high temperatures. The reason why the amount of refractory castables is now increased and has a wide range of uses. It is because the production cycle is short and the construction is convenient and quick. The iron parts and special parts of industrial furnace lining can play a better role. Even different manufacturers of refractory castables are constantly experimenting and updating the recipes of castables according to the actual use of customers, so as to better enable the castables to exert their best performance during use. Rongsheng is a refractory castable manufacturer with rich production and sales experience. Rongsheng’s advanced unshaped refractory production line has an annual output of tons. To get the price of refractory castables for free, please contact Rongsheng refractory castable manufacturers.