The amount of water added to the refractory castable is very important, and directly affects the service performance and service life of the castable. How much water should be added during the construction of refractory castables? Different binders are used in castables, and the prepared refractory castables are also different. Even the same kind of refractory cement can be used as a binder to prepare various refractory castables. The amount of water added to the castable is also different during construction. The strength and service life of castables are inseparable from water consumption.

During the construction of castables, the increase in water consumption will generally lead to a large decline in various properties. When the amount of water is large, the water will escape after heating, and the pores will increase accordingly, forming a loose structure, resulting in an overall decline in the performance of the castable and affecting the service life of the castable. Therefore, during the construction of castables, it is necessary to minimize the amount of water used during mixing.

According to the current use of castables, basically, the amount of cement is increasing, and the amount of cement added is basically canceled. Because the amount of low-cement castable high-alumina cement added is small, the amount of water added during construction is also small, and the situation of low medium-temperature strength is also overcome. If the amount of water added to the castable is too large, it is not only a coagulation problem, but the biggest reason is to affect the later use strength.

When the ratio of refractory castables and the production process are basically the same, water consumption has the best value. Generally, after the castable is produced, the manufacturer will make a sample block and do certain chemical and physical tests. Then, according to different situations, determine the optimal value of water consumption for each pouring material. Sometimes it is necessary to do certain tests or equip some binders according to the temperature on the spot during construction so that the water consumption of different castables during construction can be used at different temperatures.

Therefore, when making cement-bonded refractory castables, they should be mixed to the best fluidity. Then, according to the size of the normal temperature strength, determine the optimal amount of water.

The main points of adding water during the construction of refractory castables

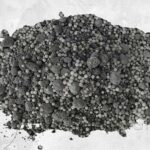

Refractory castables are divided into neutral, alkaline, and acidic. The materials are divided into high aluminum, magnesium, acid, light series, and so on. Regardless of the series, the amount of water added is different for different models and materials.

During the construction of refractory castables, drinking water with pH = 6-7.5 must be used. In general, the water content of the high aluminum series is 10-15%, the water content of the low cement series is 6-8%, and the water content of the wear-resistant series is controlled at 5.5-6.5%. The amount of water added to the spray paint is 10-15%, and the amount of water added to the corundum series is 5-6%. If it is the refractory mud for brick matching, the water addition is 20-25%, and the water added for the light series is 20-25%. Be sure not to add too much water. Adding too much water will prolong the setting time of the castable and affect the strength of use.

The amount of water added to the refractory castable also has a great influence on the internal structure. If you add too much water, the internal performance will gradually decline. As the amount of water added increases, the strength decreases, the porosity increases, and the anti-scouring ability also decrease, which seriously affects the service life.

During the construction of refractory castables, the amount of water added is determined according to the particle gradation and the ratio of the binder. The castable does not have a large amount of water and good performance. If too much water is added, the aggregate will be separated from the base material, which will affect its performance and reduce its density and corrosion resistance.

However, the amount of water added is insufficient, the fluidity cannot be achieved, the air bubbles cannot be discharged, and the internal structure cannot form density accumulation, which will still affect various performances.

Therefore, in the construction, it is necessary to follow the instructions provided by the manufacturer, add water and stir the construction reasonably, so that the performance of the refractory castable can be fully utilized.

How to judge the appropriate amount of water added to monolithic refractory castables?

Why do castables that add water in strict accordance with the construction instructions still have problems? This problem is often encountered in actual use. Most people will say that I added water strictly according to the construction instructions, why is it still too wet (too dry)? In fact, the amount of water added in the construction instructions is only a theoretical reference, and the specific amount of water added should be determined according to actual construction needs.

After determining the raw materials of castables, qualified refractory castables are produced after a series of processes. Users can use it by adding water and stirring it, but it is precisely the step of adding water that stumps many construction workers. Either the mixing is too dry, or it is too wet. I have summed up a method in many times of practices, which can well control the amount of water added so that the performance of the castable can be better exerted.

the appropriate amount of water added to monolithic refractory castables

The reference water content of general refractory castables is 8%-10%. When actually adding water, you can add water according to the principle of “small amount and many times”. Control the time well, and the mixing time of the pouring material should not be too long. After the mixing is finished, grab a handful of castables with your hands and hold them into balls (balls). If the dough disperses immediately after holding the ball, it means that the amount of water added is too small. If the spherical castable flows down from the fingers after holding the ball, it means that the amount of water added is too large. The amount of water added is appropriate only if the spherical castable does not disperse or flow out.

The amount of water to be added to the castable during construction is not only related to the raw materials, but also factors such as the construction site environment, dryness and humidity, and seasons. Only by controlling the amount of water added can the performance of the castable be maximized.