The process of using lightweight and high-strength castables for ladle insulation. The choice of insulation layer material, the traditional insulation layer is built with clay bricks, which is cumbersome in process, frequent maintenance, easy to penetrate the brick seam, low life, and high cost. The technology of unshaped refractories is becoming more and more mature, and the lightweight and high-strength castables have the characteristics of low bulk density, low thermal conductivity, and high compressive strength, and are widely used.

Preparation and Characteristics of Lightweight and High Strength Castables for Ladle Insulation Layer

The aggregate of the castable is made of floating beads, high alumina porous clinker, and alumina hollow sphere composite aggregate. The castable has the properties of low bulk density, low thermal conductivity, good thermal insulation performance, high refractoriness, and high compressive strength. Clay clinker powder and industrial alumina powder are used as powders so that the mass fraction of Al2O3 in the castable reaches 45% to 50%. Pure calcium aluminate cement is used as a binder to ensure high strength after casting without reducing the mass fraction of Al2O3. Adding an appropriate amount of fused magnesia to maintain the volume stability of the product, reduce the cracking and peeling phenomenon in use, enhance the resistance to rapid cooling and rapid heating, and improve the service life of the insulation layer.

Table 1 Performance indexes of the light-weight and high-strength castables for ladle

| Operating Temperature / ℃ | Bulk Density g/cm3 | Thermal Conductivity / w·(m·K)-1 | Compressive Strength / MPa | Line Change Rate After Heating / % (1400 ℃) | W(Al2O3) |

| 1200 ~ 1400 | 1.5 ~ 1.7 | 0.41 ~ 0.52 | 7 ~ 15 | +0.3 ~ (-1.0) | 45 ~ 50 |

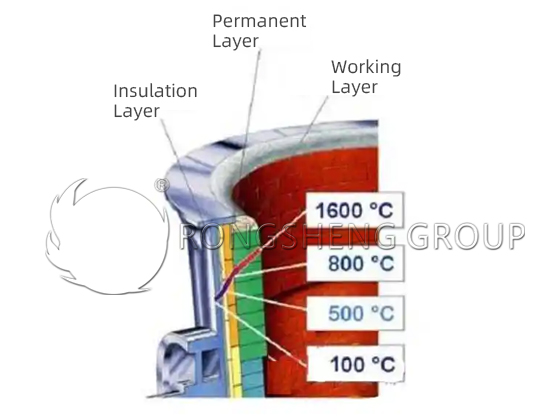

Thickness Design of Ladle Insulation Layer

The refractory lining of the ladle requires a working layer thickness of 180mm, a minimum use thickness of 60mm, and service life of not less than 25 times. Considering the thermal insulation performance of the ladle and the service life of the working layer, the thickness of the thermal insulation layer of the clad wall is determined to be 80mm. The thickness of the bottom insulation layer is 140mm.

Production of tire molds

Design the insulation layer mold according to the designed insulation layer size and the size of the cladding. In order to facilitate the vibrating and ramming of the castable, so that the castable fills the entire insulation layer and facilitates de-moulding, the tire mold is made into a split structure of upper and lower layers. The taper is the same as that of the cladding, the outer diameter of the lower mold is 190mm smaller than the inner diameter of the cladding (10mm to 20mm for the thermal insulation layer), and the outer diameter of the upper mold is 180mm smaller than the diameter of the inner wall of the cladding (10mm to 20mm for the thermal insulation layer). The welding of the tire mold steel plate should be smooth and flat, with a support plate inside to prevent deformation of the tire mold, and hooks are welded on the support plate to facilitate lifting.

Pouring Construction of Castables for Ladle Insulation Layer

The overall knotting process of lightweight and high-strength castables is adopted. The process is carried out in stages, and each batch of castables should be fully stirred in the mixer. The amount of water added is controlled at 10% to 15%.

- ① Knot the bag wall and evenly coat the outer wall of the lower mold with a layer of release agent put it in the bag, and fix it, and the gap between the mold and the insulating layer is uniform. Then pour the stirred castable into the gap between the mold and the heat insulating layer, taking care not to peel off the heat insulating castable material or roll it into the castable. Then use a vibrating rod to vibrate the castable evenly and densely. After the lower layer is knotted, put the upper layer of the mold in and tie the knots in turn.

- ②Dry naturally for 24h-48h, and the mold will come out. Install the seat brick and the breathable brick mold, and then use the evenly stirred castable to tie the bottom insulation layer.

- ③ Natural drying for 12h ~ 24h, the mold comes out. Then natural curing for more than 72h, and finally baking.

Baking of ladle insulation

The water content of the poured insulation layer is relatively large, and the water in the castable needs to be discharged by baking to increase the strength of the insulation layer. In order to prevent the thermal insulation layer from bursting due to the excessive heating speed, the baking is carried out in strict accordance with the heating speed and holding time specified by the process. The total baking time shall not be less than 15h.

Rongsheng Unshaped Refractory Castable Manufacturer

Rongsheng Unshaped Refractory Castable Manufacturer is an unshaped refractory manufacturer with rich experience in production and sales. Our environmentally friendly fully automatic monolithic refractory castable production line has an annual output of 60,000 tons. Our refractory materials have been sold to more than 80 countries all over the world, eg, South Africa, Philippines, Chile, Malaysia, Indonesia, Vietnam, Kuwait, Turkey, Zambia, Peru, Mexico, Qatar, Egypt, Russia, Kazakhstan, etc. Moreover, our technical team is also keeping pace with the times, providing high-quality materials for the refractory lining of high-temperature industrial furnaces. Including light and high-strength castables for ladle insulation, ladle wear-resistant refractory castables, etc. Contact us for free quotes and samples.