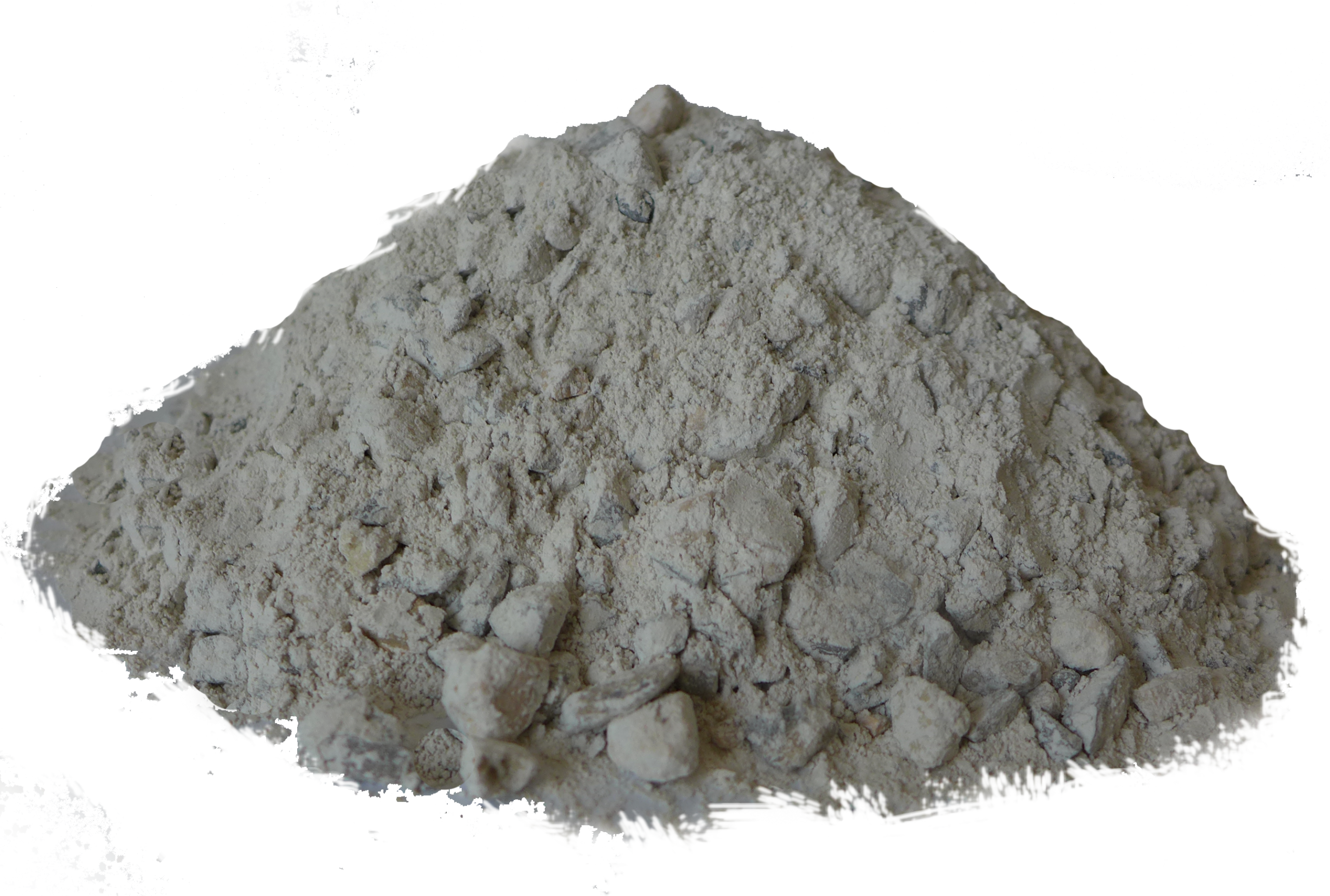

Nowadays, many industries have been widely used in a variety of refractory castable, construction industry for castable application is the most, a lot of people are more familiar with the castable, but the novice is not very understand. So, wear resistant castable for sale in the construction of matters to note? We will give you a detailed explanation of the following!

Precautions For Wear Resistant Castable

1. All metal to castable contact surface should be coated with asphalt or wrapped with ceramic fiber paper.

2. The gap of the retractor slot of the retractor brick should be filled with mortar.

3. Mortar joints between all wear resistant firebricks shall be <2.

4. The mortar between each wear-resistant firebrick should be filled, do not leave gaps, otherwise the flue gas will get in when the boiler is running, aggravating the erosion or peeling of the wear-resistant lining.

5. When laying wear resistant bricks, do not cut in principle. If cutting is really needed, each brick cannot be less than 1/2. If it cannot be satisfied, two pieces can be cut at the same time.

6. All the bricks from bottom to top close to push pull each have pull hook, on all support support plate, next brick all should be long shape brick and cooperate to give expand joint, in order to form a whole stable furnace wall body.

7. All mortar joints between bricks shall be coated with refractory resistant mortar, and all bricks shall be laid along the joints. If the corner or end face of bricks is broken, the bricks shall be replaced in case of cracks.

8. When laying bricks, tap them with glue or wooden hammers to make them stick together. Do not use hammers.

9. During the construction of RS high strength wear resisting castable, the amount of water added should be strictly controlled. Generally, the amount of water added should be 6-8. The stirring should be uniform.

10. Wear resistant castable for sale appliances used during construction must be clean and free from contamination, especially chemical contamination.

11. High strength wear resistant castable is formed with applied vibration motor during construction, and vibrates evenly, and the vibrator rod is pulled out slowly during vibration, so as to avoid cavitation of HF high strength wear resistant castable.

12. The wear resistant castable for sale should be checked after demodulation of this series of wear castable. Hammer can be tapped gently. If a clear echo is sent out, it indicates that the castable is relatively dense. At the same time can not appear honeycomb, pockmark. If the honeycomb, pockmarked area is larger, it should be partly chipped out for new construction.

13. After demoulding, the RS high-strength wear-resistant castable lining, which has been inspected and qualified, can be kept warm for 5-7 days before entering the next process.

For wear resistant castable in the construction of the matters needing attention, this problem must have been known. If you have any questions about this, please contact us directly. We will serve you wholeheartedly.