Refractory aggregate is a key component of refractory castables. Its type, grade, and particle size distribution are key factors influencing various castable properties.

Performance Requirements for Refractory Aggregates

High-Temperature Stability

Refractory aggregates must exhibit excellent chemical stability at high temperatures, resisting chemical reactions with the melt and gases within the furnace and maintaining their structure and properties. They must also possess a low coefficient of thermal expansion and good thermal shock resistance to withstand rapid temperature fluctuations without breaking.

Most refractory aggregate particles are multiphase and polycrystalline. Therefore, their shape is influenced by the crystal structure, crystallization behavior, and impurity content of the various phases in the material, as well as the processing methods used.

For example, mullite produced by the electric fusion process, because it precipitates from the melt, is mostly euhedral. Therefore, due to its crystallization behavior, mullite often forms columnar polycrystalline aggregates. During crushing, the grains fracture along the longitudinal direction, where the bonding strength is poor, resulting in the formation of columnar polycrystalline particles.

Mullite produced by sintering, however, has crystal growth that is constrained by the surrounding environment. This results in morphologies such as needles, columns, plates, and granules, with irregular interlacing growth. Consequently, the crushed particles have irregular shapes, including flakes, needles, columns, and fusiform shapes.

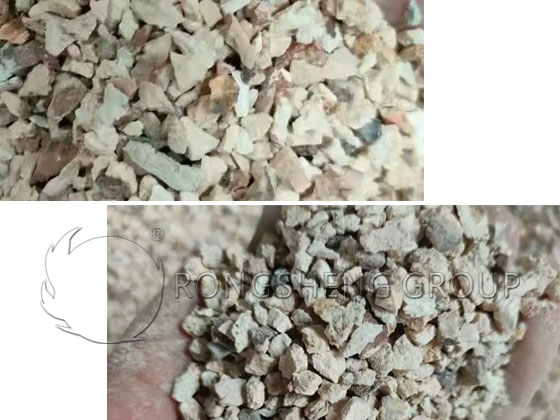

The morphology of crushed refractory aggregate particles also depends on the density of the material and the crushing method. For example, for ultra-dense and high-density high-alumina clinker, impact or extrusion crushing methods often produce flake or fusiform aggregate particles. Grinding crushing methods often produce irregular granular or nearly spherical shapes. Therefore, to produce aggregate particles that are most suitable for monolithic refractory materials, a more appropriate crushing method should be selected.

Mechanical Strength

Under high-temperature operating conditions, refractory aggregates must withstand the impact, abrasion, and pressure of the furnace charge. Therefore, they must possess sufficient mechanical strength, including compressive strength, flexural strength, and wear resistance.

Particle Size Distribution

A reasonable particle size distribution is crucial to the performance of refractory materials. Typically, refractory aggregates are composed of particles of varying size grades to form a tightly packed structure, enhancing the material’s density and strength.

In the production of monolithic refractory materials, refractory aggregates are generally divided into coarse, medium, and fine aggregates. The particle size ranges of coarse, medium, and fine aggregates are related to the critical particle size (i.e., particle size) of the aggregate.

- For example, if the aggregate particle size is 8 mm, the coarse aggregate particle size range is 8-3 mm, the medium aggregate particle size range is 3-1 mm, and the fine aggregate particle size range is 1-0.088 mm. Particles smaller than 0.088 mm are not considered aggregates but are instead called powder (or matrix).

- For example, if the aggregate particle size is 3.5mm, the coarse aggregate particle size range is 3.5-1.5mm, the medium aggregate particle size range is 1.5-0.5mm, and the fine aggregate particle size range is 0.5-0.074mm.

The ideal aggregate particle size distribution should achieve the most compact packing. That is, the gaps left by the coarse particles are filled by the medium particles, and the tiny gaps left by the medium particles are filled by the fine particles, thus forming a skeleton. The remaining gaps are filled by the powder. However, due to the irregular shape of refractory aggregate particles, achieving an ideal aggregate particle size distribution is difficult in actual production. Aggregate gradation is usually determined through experiments, and the typical ratio of coarse, medium, and fine aggregate is (35-45):(30-40):(15-25).

Refractory Aggregates for Refractory Castables

-

Castable performance can be improved through refractory aggregate grading.

The refractory aggregate grade, impurity content, sintering quality, and storage time of the raw materials also affect castable performance. As the Al₂O₃ content increases, the castable’s refractoriness and refractoriness under load also increase. When the post-firing linear change decreases, or when the material is underfired or contains a high impurity content, the refractoriness and refractoriness under load decrease, and the post-firing linear shrinkage increases.

Before making refractory castables, it is important to select well-sintered, high-purity bauxite and carefully grade the refractory aggregate to improve the various properties of the castable.

-

The particle size of the refractory aggregate is determined by the thickness of the lining.

The more irregular the shape of the refractory aggregate particles, the better. Avoid using long, flake-shaped particles. The particle size is determined by the thickness of the lining.

-

The Importance of Refractory Aggregates in Refractory Castables.

The grade, impurity content, sintering quality, and raw material quality of the refractory aggregate significantly influence the density of the castable. These are the most basic principles that must be followed when determining the aggregate particle size gradation. The values may change after adding cement and powder, but the basic principles remain the same.

When high-alumina cement is added to the castable, the material fluidity remains the same, but the water requirement is different. A better aggregate particle size gradation reduces water usage, increases bulk density, and reduces apparent porosity. Furthermore, the compressive strength at room temperature and after firing is also higher. When fine aggregate is present in larger quantities, its particle surface area increases, requiring the addition of more cement and powder to encapsulate the aggregate and prevent the aggregate from becoming densely packed. While a higher cement content also requires more water, encapsulation is crucial. Therefore, a proper mix ratio is crucial to avoid compromising the performance of the refractory castable.

Refractory aggregate particle grading is generally a three-level gradation, with a high-quality gradation characterized by larger particles at the ends and smaller particles in the middle. When crushing refractory aggregate, the ratio of large, medium, and small particles should be controlled to prevent segregation of oversized particles, thereby creating a denser castable.

Applications of Refractory Aggregates

Refractory aggregates are widely used in high-temperature industries such as steel, nonferrous metallurgy, glass, cement, and ceramics. The following are some specific application examples:

-

In Steelmaking

High-alumina refractory aggregates are commonly used in the shaft and waist of blast furnaces to withstand the erosion of high-temperature molten iron and slag, as well as the impact of furnace charge. Magnesia refractory aggregates are often used in electric furnace linings. Their excellent slag resistance and high-temperature resistance effectively extend the service life of electric furnaces.

-

In the Glass Industry

Silica refractory aggregates are the primary material for kiln refractory linings. For example, the tin baths in float glass production lines use refractory materials made from high-quality silica refractory aggregates, which can withstand temperatures up to 1600°C and resist the erosion of molten glass.

-

In Cement Production

The firing zone of rotary kilns typically utilizes refractory materials made from magnesia-chromium refractory aggregates to withstand the abrasion and chemical attack of high-temperature clinker.

-

In tunnel kilns in the ceramic industry

Refractory bricks made from mullite refractory aggregate are used in the kiln roof and walls, ensuring long-term stability and energy efficiency.

In short, refractory aggregates, as a crucial component of refractory materials, play an irreplaceable role in ensuring the safe and efficient operation of high-temperature industries. Continuous in-depth research and innovation in the performance, preparation processes, and applications of refractory aggregates will provide strong support for the development of high-temperature industries.