With the continuous progress of the production and use technology of monolithic refractories, especially the development of low-cement refractory castables, self-flowing castables, and wet injection technology. The refractory lining used in the new dry-process cement kiln system has gradually developed into a castable-based lining structure.

Multifunctional refractory castables have many functions such as high early strength, high thermal strength, alkali resistance, wear resistance, and heat insulation. For the vulnerable parts in the new dry process cement kiln system. Such as the kiln mouth, the top of the kiln door cover and the blanking slope, the low wall of the grate cooler, and the high-temperature area on the top of the grate cooler. Coal injection pipe, tertiary air pipe elbow, and other parts. Various refractory castables have different damage mechanisms under different conditions of use parts. Because the vulnerable parts in the new dry-process cement kiln system are in harsh environments such as high temperature, cement clinker erosion, abrasion, rapid cooling, rapid heating, etc. And it is located in special parts of the port, and the service cycle of these parts seriously restricts the life of the kiln lining of the whole kiln. According to the specific use characteristics of each part of the kiln, the development trend of refractory castables for the cement industry is as follows.

- Improve the wear resistance of wear-resistant castables.

- Improve the thermal shock resistance of wear-resistant castables.

- Reduce Fe2O3 content.

- Reduce the bulk density of the castable. Reducing the load on the equipment Reduce the bulk density of the castable on the premise of ensuring wear resistance and thermal shock resistance.

Low Cement Refractory Castable for Cement Kiln Lining

Low cement refractory castables for cement kilns mainly include high alumina, mullite, and corundum refractory castables. This series of products has the characteristics of high strength, erosion resistance, wear resistance, and excellent performance. At the same time, the material can be made into a quick-baking explosion-proof castable according to the user’s baking time requirements.

Rongsheng monolithic refractory castables are the first to produce low-cement products with reliable quality and stable performance. It is widely used in blast furnace tap ditch, cast iron furnace tap trough, integral powder spray gun for molten iron pretreatment, high-temperature burner lining, heating furnace water cooling tube wrapping lining, etc.

Corundum and chromium-containing corundum low-cement castables are used for the lining of some parts of the refining device outside the molten steel furnace. It is also used in the lining of power frequency induction furnaces, the high-temperature wear-resistant lining of the petrochemical catalytic cracking reactor, etc. The low-cement refractory castable has the properties of high strength, alkali resistance, and wear resistance, which is obvious to all who have used it.

Index of low cement refractory castable for cement kiln

There are three common low-cement refractory castables, where low refers to less cement content in the product. The cement content of castables is as high as 10-30%, and the cement content of low-cement castables is between 3%-8%, so there are also 1% of ultra-low cement castables.

How to cure and bake low cement castable in the rotary kiln?

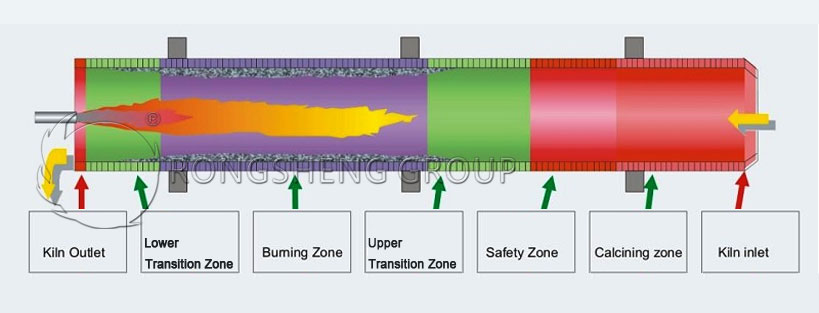

Low cement castables are widely used in new dry process cement rotary kilns. It is mainly used in the rear kiln mouth, kiln door, decomposition furnace, cooler and other parts. As we all know, the construction of refractory castable is mainly composed of three links, namely mixing, pouring, and curing. So how to maintain and bake it?

- Maintenance

The tools that low-cement castables need to use in the curing process are polyethylene plastic film, straw bags, etc.

Ambient temperature requirements and controls. The curing temperature of the casting body is preferably between 15-35 ℃. Outside this temperature range, corresponding heating or cooling measures should be taken. Otherwise, the performance of the product will be degraded.

conservation. After the castable is hardened, the surface of the construction body must be covered with polyethylene plastic film immediately. A wet straw bag is added on top to prevent water evaporation and promote cement activation. After hardening, it is forbidden to beat and vibrate within one day. According to the hardening situation, the mold can be removed after 24-30 hours of hardening, or it can be removed in 3 days. After de-molding, continue curing for 2 days. Continue to cover with polyethylene film and wet straw bags during maintenance. After 3 days of curing, remove the polyethylene plastic film and a wet straw bag. Let the cast body dry naturally in the air for 1 day before baking.

- Baking

One of the most critical aspects when using castables during baking. Because the casting body is relatively thick and dense, the water is not easy to discharge. Therefore, it is absolutely forbidden to heat up too fast during baking, otherwise, it will cause the casting body to crack.