In steelmaking, the container for molten steel is generally called a ladle, which is mainly used to store and transport molten steel. When tapping steel, 1650℃ molten steel is directly poured into the ladle. At this time, the steel is melted, so why is the container for molten steel (ladle) safe and sound?

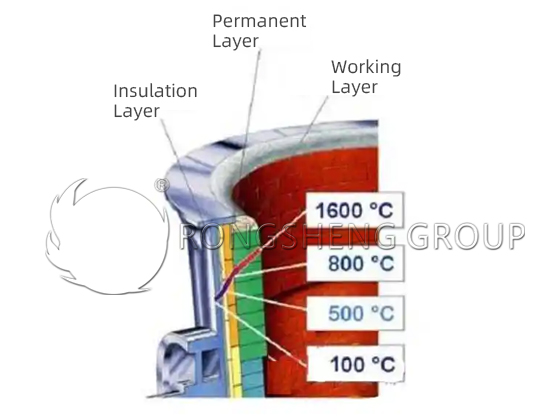

First, we need to understand the main components of the ladle. From the outside to the inside, the ladle is composed of a metal shell, an insulation layer, a permanent layer, and a working layer.

The insulation layer is close to the steel plate of the ladle shell. Its function is to keep warm, prevent the ladle shell from deforming, and reduce the heat conduction of the ladle wall lining.

The function of the permanent layer is to prevent the molten steel from burning through the metal shell when the refractory material of the working layer in the innermost part of the ladle, which is in direct contact with the molten steel, is partially eroded or thinned.

The working layer is in direct contact with the high-temperature molten steel, and at the same time it is subjected to the mechanical scouring of the molten steel and slag, so the refractory material of the working layer is the most important thing in the ladle lining. The height of a ladle also depends on the selection of working layer materials and masonry technology.

After the temperature of the molten steel passes through the above layers, the temperature that is finally transmitted to the ladle shell wall is only about 300℃. The temperature of the working layer is 1600℃, the temperature of the permanent layer is 800℃, and the temperature of the insulation layer is 500℃. This is why the ladle shell will not be melted.

Simply put, the container (ladle) that holds molten steel will not melt, all thanks to the refractory lining inside. Therefore, the selection of durable, high temperature and wear-resistant refractory materials is the key factor to ensure the service life of the ladle. The refractory materials of the ladle lining working layer are generally magnesia-alumina-carbon bricks and carbon composite refractory materials. The thickness of magnesia-alumina-carbon bricks is about 110~120mm. It needs to withstand high temperature, molten steel and mechanical scouring.

The Use Temperature and Requirements of the Castables for the Ladles of Foundry

The selection of castables for the ladle of the foundry is crucial. It not only affects the service life of the ladle, but also affects the efficiency and safety of production. The selection of suitable castables needs to be determined according to the specific working conditions to ensure its refractory performance and construction convenience.

- Refractoriness of castables for ladle. The refractoriness of the AI2O3-SiC series of materials is between 1580-1770℃, which ensures the stability of the ladle in a high temperature environment.

- Compressive strength. The compressive strength of the castable reaches 80MPA, which means that it can withstand the erosion of molten iron and extend its service life.

- Use temperature. The use temperature of the castable for the ladle is generally not less than 1650℃ to meet the needs of high temperature operations.

- Construction and maintenance. The construction of the castable should be convenient and easy to maintain to adapt to the daily maintenance work of small and medium-sized foundries.

- Thermal shock stability. The castable needs to have good thermal shock resistance to cope with the thermal stress caused by temperature changes.

- Performance requirements. The amount of water added to the castable should not exceed 7.3%, the number of thermal shocks should reach more than 35 times, the line change after firing should be between 0.3% and 0.8%, and the line change after re-firing should be between 0 and 0.2%.

Through these requirements, we can select the castable suitable for the foundry ladle to ensure that it is safe and efficient during use.

Steel Ladle Castables Rongsheng Manufacturer

Ladle castables are a special material used in the ladle, which can withstand high temperature and high pressure, and needs to have good fire resistance and chemical stability.

Performance Characteristics of Rongsheng Steel Ladle Castables

- Good fire resistance. Ladle castables need to withstand high temperature and high pressure, so they need to have good fire resistance. Its refractoriness can reach above 1650℃, and it can work stably at high temperature.

- Good chemical stability. Ladle castables need to resist various chemicals in molten steel, so they need to have good chemical stability. It can work stably in molten steel and will not react with substances in molten steel.

- Good thermal insulation. Ladle castables need to keep the temperature of molten steel stable, so they need to have good thermal insulation. It can transfer heat in molten steel and keep the temperature of molten steel stable.

- Good compactness. Ladle castables need to fill the internal space of the ladle, so they need to have good compactness. It needs to fill the inner space of the ladle tightly to achieve the best insulation effect.

- Good unloading. Ladle castables need to be easily unloaded, so they need to have good unloading properties. It needs to be easily washed and peeled off by molten steel to facilitate the discharge of molten steel.

Rongsheng Refractory Castables Factory‘s ladle castables have good fire resistance, good chemical stability, good thermal insulation, good compactness and good unloading properties. These properties can make the ladle castable work stably in the ladle and provide guarantee for the efficient smelting of molten steel. To purchase ladle and iron ladle castables, please contact Rongsheng for free samples and quotations.