What are the advantages of phosphate-bound high-aluminum castables? Phosphoric acid combined with high aluminum castable is one of the castables. Compared with other castables, its advantage is that high-aluminum phosphate castables have the advantages of high medium-temperature strength, good thermal shock resistance, wear resistance, and good air tightness.

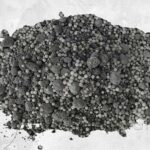

Phosphoric Acid Bonded High Aluminum Castable

Phosphoric acid-bonded high-aluminum castables are not only resistant to high temperatures and corrosion but also have excellent thermal shock resistance and wear resistance. It is widely used in metallurgical heating furnaces water-cooled tube wrapping, heating furnace top prefabricated blocks, high-temperature flame furnace burner bricks, and kiln car table prefabricated blocks. The overall lining of induction furnaces in the precision casting industry, as well as the abrasive parts of power plant boilers and other thermal kilns.

Phosphoric acid combined with high alumina castables generally uses high alumina cement as a setting accelerator. When the amount of high alumina cement is increased, the castable hardens and sets too quickly, making construction difficult. When the amount of high alumina cement is increased, the castable does not solidify, and there is no way to demould it later, and the castable needs to be baked after demoulding to develop strength.

Although phosphoric acid combined with high-aluminum castables has many advantages, the amount of high-aluminum cement added is difficult to control and the construction is too difficult, which affects the progress of castable construction. These problems also hinder the widespread application of high-aluminum phosphate castables. In a large number of practical applications by castable manufacturers, continuous exploration and research have found that fused spinel fine powder has an accelerating effect on phosphoric acid. This procoagulant effect is relatively mild and easy to control. At the same time, the phosphoric acid-bound castable can produce high strength without baking after demolding.

Phosphoric acid combined spinel high alumina castable, after adjusting the formula of the castable manufacturer and adding fused spinel powder. In various industrial kilns and in various temperature ranges, it has higher strength than ordinary phosphate-bonded high-aluminum castables. The high-temperature resistance is more than 200 ℃ higher than that of ordinary phosphoric acid combined with high aluminum castables. At the same time, it can produce strength without baking, overcoming the disadvantages of the difficult construction of ordinary phosphate-bonded high-aluminum castables. The adjusted phosphoric acid combined with high aluminum castable material does not absorb moisture after natural curing and is not afraid of water, which brings great convenience to on-site construction and storage and transportation of prefabricated parts. Its good thermal shock resistance greatly extends the service life of furnace linings or objects working under alternating hot and cold conditions.

High Alumina Cement Combined Refractory Castable

High alumina cement refractory castables are made by using high alumina cement as a cementing agent, mixing refractory aggregates and powders in proportion, adding water, mixing, shaping, and curing. Refractory aggregates and powders are generally made of clay, high alumina, corundum, etc. Commonly known as clay castables, high alumina castables, corundum castables, etc.

The main mineral of high alumina cement is calcium aluminate (CA), which hydrates quickly and does not precipitate calcium hydroxide. Therefore, refractory castables formulated with high alumina cement have the characteristics of rapid hardening and high strength.

Factors Affecting the Performance of Aluminate Cement Bonded Castables

The general ratio of aluminate cement combined with refractory castables is. Refractory aggregate 62%-76%, refractory powder 17%-28%, cement 10%-24%, water 7%-14%, and appropriate amount of admixtures. This is also the general ratio of refractory castables. On the premise of meeting construction and use requirements, the amount of cement and water should be minimized. This type of castable is divided into many categories based on aggregate types, and many factors affect performance.

- Cement dosage.

Cement is one of the important components of refractory castables. It is an important material that determines the strength of the material and also affects other properties. Different types of cement and their dosages have different effects on performance. As the amount of cement increases, the normal temperature compressive strength increases, and later the compressive strength and high-temperature compressive strength decrease, and the linear change after burning changes from expansion to contraction. Therefore, while ensuring that the normal temperature strength meets the requirements, the amount of high-alumina cement should be reduced as much as possible to improve the high-temperature performance of refractory castables. However, while reducing the amount of cement, it is necessary to appropriately increase the refractory powder so that the mixture of powder and cement can fully wrap the refractory aggregate.

- Water consumption.

When configuring aluminate cement combined with refractory castables, the amount of water used is very important. When too much water is used, the water will overflow after heating, resulting in increased pores and loose structure, resulting in a decline in overall performance. Therefore, under the conditions of ensuring construction, the amount of water added should be reduced as much as possible. Without adding a water-reducing agent, the suitable water content of aluminate cement castable is 10%-13%.

- Refractory powder dosage.

The type, fineness, and dosage of refractory powder are important factors affecting the performance of castables. The fineness of the powder directly affects the strength, volume density, and apparent porosity of the castable. The finer the refractory powder, the better the performance of the castable. When the amount of powder is small, the mixture with cement cannot completely wrap the aggregate, resulting in a loose structure. When the amount of powder is too much, there will be a significant surplus of aggregate wrapped in the mixture with cement, resulting in an increase in the amount of water used and a large shrinkage during high-temperature sintering.

- Amount of refractory aggregate.

The variety, grade, and particle matching of aggregates are the main properties that affect the performance of castables. It plays a skeleton role in the castable. The aggregates are divided into coarse aggregates and fine aggregates. It is very important to match the particles of the aggregates. The most ideal particle gradation is that the gaps caused by coarse aggregate are filled by the fine aggregate, and the gaps between the two are filled by powder, with no shortage or surplus.

In addition, high alumina cement refractory castables can also be added with admixtures (such as water-reducing agents, etc.) to improve construction performance and fire resistance.