Low cement castables have the characteristics of high density, low porosity, high strength, low wear, thermal shock resistance and erosion resistance. Low cement castables not only have the characteristics of traditional refractory materials, but also adopt the most advanced ultrafine powder application technology to improve the medium temperature strength and high temperature volume stability of the castables. The organizational structure of the product forms a firm anchor-shaped multi-directional crystal structure at high temperature. The overall structural connection stability of the lining is ensured, and the service life is increased by 3 times compared with traditional castables.

Application of Different Types of Low-Cement Castables

Low-cement and ultra-low-cement refractory castables have been widely used in industrial kilns in the fields of metallurgical industry, petrochemical equipment, machinery equipment manufacturing and decorative building materials at this stage, and have shown good use effects and economic benefits. Different types of low-cement castables play specific roles in various application fields as follows:

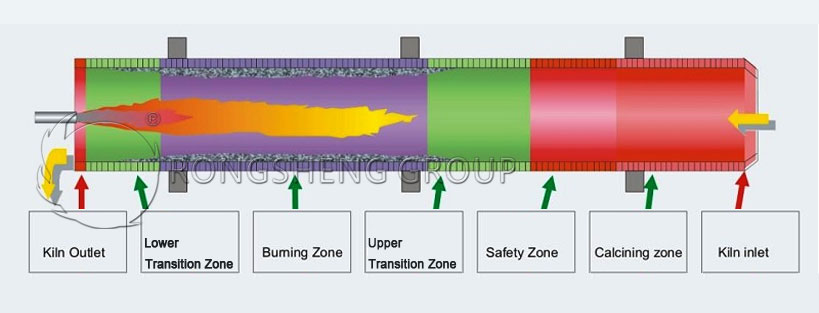

- Clay and high-alumina low-cement castables can be used as lining materials for various heat treatment furnaces such as hot blast furnaces, heating furnaces, soaking furnaces, and rotary kilns.

- Mullite low-cement castables are used for various high-temperature burner linings, x water-cooling pipe cladding and other applications.

- Corundum and chromium-containing corundum low-cement castables are suitable for the refining equipment parts outside the molten steel furnace, the lining of the power frequency induction furnace, the high-temperature wear-resistant lining of the petrochemical catalytic cracking reactor, and other occasions.

- Al2O3-SiC-C Low cement castables can be used for the lining of blast furnace tapping troughs, cupola tapping troughs, integral powder spraying guns for molten iron normalization treatment and other parts.

- Low cement castables of refractory and Cr-containing refractory can be used as linings of the triangular area of the top of the iron-making electric arc furnace and the linings of the components of the external refining equipment of the molten steel furnace. For example, the overall spray gun lining for the spouting metallurgical industry, the RH and DH vacuum pump degassing device and the prepreg tube lining, the DC induction furnace lining, and the high temperature wear-resistant lining of the catalytic cracking tubular reactor of the petrochemical equipment.

- Low cement castables of MgO-Al2O3 or Al2O3-MgO-Al2O3 are used as lining materials for equipment such as ladles and tapping troughs.

In summary, different types of low cement castables play an important role in various industries and have been widely used and promoted.

Advantages and Characteristics of Rongsheng High-Strength Low-Cement Castables

Rongsheng Refractory Castables Manufacturer has rich experience in the production and sales of refractory materials. Rongsheng’s environmentally friendly fully automatic amorphous refractory production line provides a reliable guarantee for the timely delivery of Rongsheng’s high-quality refractory castable products. After years of practical experience, Rongsheng has discovered the application advantages and characteristics of high-strength low-cement castables, which can effectively extend the service life of high-temperature industrial furnace linings. If you need to buy high-strength low-cement refractory castables, please contact Rongsheng for free samples and quotes. Happy to share and make progress together. Next is the advantages and characteristics of Rongsheng’s high-strength low-cement castables.

- Improve the refractoriness and high temperature strength of the refractory lining.

Due to the low CaO content in low cement castables, the formation of low eutectic phases in the material can be reduced. Thereby improving the refractoriness, high temperature strength and resistance to slag erosion, especially the cement-free castable has better performance.

- The refractory lining has low porosity and high bulk density.

The amount of mixing water used in the construction of low cement castables is only 1/2 to 1/3 (about 4% to 6%) of ordinary low cement castables. Therefore, the porosity is low and the bulk density is high.

- After the construction of the refractory lining is completed, less cement hydrate is generated.

After the low cement castable is formed and cured, less cement hydrate is generated, and even during heating and baking, there is no phenomenon of a large number of hydration bonds being destroyed and the medium temperature strength being reduced. The low cement castable will gradually sinter as the heat treatment temperature increases, and the strength will gradually increase.

- It can improve the structural stability of the refractory lining.

Low cement castable combines the characteristics of traditional refractory materials, adopts ultrafine powder application technology, and significantly improves the medium-temperature strength and high-temperature volume stability of the castable, so that the product’s organizational structure forms a firm anchor-shaped multi-directional crystal structure at high temperatures. It ensures the overall structural connection stability of the lining, and its service life can be increased by 3 times compared to traditional castables.