Refractory mortar is an unshaped refractory material composed of powdered materials and binders, used for preparing slurries. The powdered materials are made from fully sintered clinker (such as high-alumina clinker, calcined silica, magnesia, etc.) or other volume-stable refractory raw materials (such as silica, wax stone).

Rongsheng Refractory Mortar Manufacturer

The powder used to make refractory mortar can be fully sintered clinker and other volume-stable refractory raw materials. The particle size of the powder depends on the application requirements, with a generally limited particle size of less than 1mm, and sometimes less than 0.5mm or even finer. A reasonable particle composition has a significant impact on ensuring the mortar’s workability, as do the binders and admixtures. Ordinary refractory mortars use bonded clay as the binder. However, chemical binders are increasingly widely used. Adding various admixtures to refractory mortar can improve its workability. For example, adding water-retaining agents to extend the water loss time and ensure construction quality; adding plasticizers, even in small amounts, can increase the mortar’s plasticity; adding dispersants to improve the mortar’s fluidity, etc.

Refractory mortars can be classified into hydraulic, thermohardening, and air-hardening refractory mortars based on their binder setting and hardening characteristics. Hydraulic refractory mortars use cement as a binder and can be used at room temperature or in places where they may frequently come into contact with water or moisture. Thermosetting refractory mortars are commonly made with thermosetting binders such as phosphoric acid or phosphates. After hardening, these mortars exhibit high strength at various temperatures, low shrinkage, tight joints, and strong erosion resistance. Air-hardening refractory mortars commonly use air-hardening binders such as sodium silicate. These mortars ensure tight joints in masonry.

Depending on the material of the refractory powder used, commonly used refractory mortars can be classified as: clay-based, silica-based, high-alumina-based, magnesia-based, and insulating. Refractory mortar is mainly used as a contact and surface coating for refractory brick masonry. When used as a jointing material, its quality has a significant impact on the lifespan of the masonry. It can adjust dimensional errors and irregular shapes of bricks, making the masonry neat and load-bearing. It also helps the masonry form a strong and tight whole, resisting external damage and preventing the infiltration of molten metal.

Corundum Refractory Mortar

The formulation of corundum refractory mortar mainly uses sintered corundum clinker or fused alumina with a diameter of 0.5-0.63 mm and finer. Fused alumina with a diameter of 5-7 μm or industrial alumina with a diameter of less than 5 μm is used as a binder. To ensure the shrinkage of the refractory clay during air and firing, the industrial alumina content in the formulation should not exceed 15%-20%, while the content of ultrafine fused alumina powder should reach 40%-50%. 10% of the refractory mortar is introduced with orthophosphoric acid (density 1.72 g/cm³).

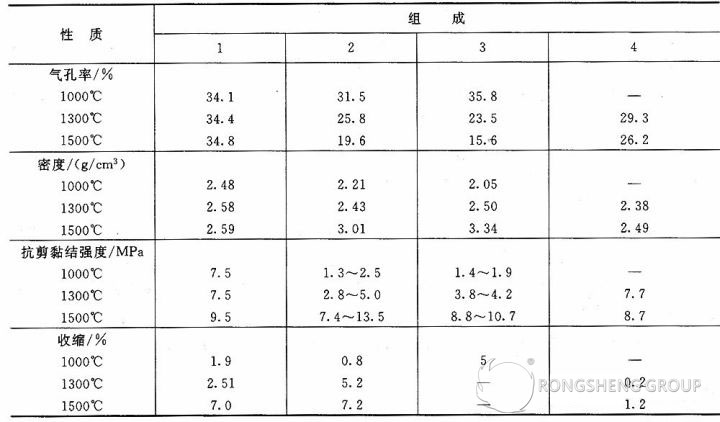

Using corundum clinker and introducing less than 0.1% fermented alcohol waste liquid can improve the plasticity of the slurry and reduce its water content. This refractory mortar has a normal moisture content of less than 19%, a weight loss of 1.8% when heated to 110°C, and an apparent porosity of 26%. As shown in Table 1, the refractory clay has sufficient shear bond strength after firing at 1000-1500°C.

Note: Component 1 is a refractory mortar primarily composed of sintered corundum, with particles smaller than 0.5 mm, 10% phosphoric acid, and 0.1% fermented alcohol waste liquid. Component 2 is a refractory mortar primarily composed of industrial alumina, with particles smaller than 30 μm, 5.5% polyphosphoric acid, and 0.1% fermented alcohol waste liquid. Component 3 is a refractory mortar primarily composed of light-burned alumina, bonded with sodium pyrophosphate. Component 4 is a refractory mortar primarily composed of high-alumina clinker, 10% clay, 0.1% fermented alcohol waste liquid, and 0.15% sodium carbonate.

According to Table 1, the shear bond strength of the refractory mortar is related to the final porosity; as porosity increases, the shear bond strength tends to decrease. To maintain the uniformity of the moisture content of the corundum refractory mortar at 2.5%, some dust needs to be removed, and 2.5% CaCl2 needs to be introduced. This increases the moisture content of the slurry to 24%–27%, without reducing the cohesive strength between the refractory mortar and the corundum refractory material. The shear bond strength after firing at 1000°C is 1.4–2.0 MPa, and reaches 10 MPa after firing at 1500°C.

Phosphate-bonded corundum refractory mortar can withstand 40 cycles of repeated water exchange at 1300°C without cracking. Corundum refractory mortar containing approximately 96% alumina has a refractoriness of 2000°C. Reducing the alumina content in the refractory mortar to 90%–91% slightly decreases the refractoriness, and the deformation initiation temperature under a 0.2 MPa load drops to 1580°C.

High-Alumina Refractory Mortar

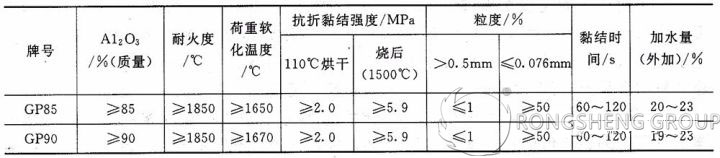

The technical properties of high-alumina refractory mortar are shown in Table 2.

Storage and Usage Principles of High-Alumina Mortar

High-alumina mortar is the jointing material for high-alumina refractory bricks, mainly used for bonding bricks. Its storage time affects its performance, and its continued usability can be determined.

Judging the Storage Condition of the Binder

- Check the Binder Packaging

First, check if there is a separately packaged binder in the high-alumina refractory mortar. If there is a separately packaged binder, and the storage time exceeds 6 months, it cannot be used and needs to be replaced.

If there is no separately packaged binder, take a small amount of refractory mortar and smell it. If there is an odor, it means that the binder was added to the refractory powder during production; if there is no odor, it means that the binder was not added.

- Advantages of No Added Binder

High-alumina mortar without added binder is in its optimal state. It can be remixed with binder and used again, thus ensuring its bonding performance.

Judgment of Refractory Mortar with Added Binder

If the high-alumina refractory mortar has had a binder added directly during production and has been stored for more than 6 months, the following test is required to determine its usability:

- Test Preparation

Weigh 1 kg of refractory powder, add 20%-25% drinking water, and stir to form a slurry. Prepare two refractory bricks of the same material.

- Test Procedure

Take a portion of the refractory mortar and evenly spread it on one refractory brick, smooth it out, and place the second refractory brick on top. Rub the two refractory bricks back and forth approximately 15 times.

- Result Judgment

If the two refractory bricks can bond together, the high-alumina refractory mortar is still usable. If the refractory bricks cannot bond, add an appropriate amount of binder in a reasonable proportion and repeat the above test. If the refractory bricks bond successfully, they can be put into use.

Summary of High-Alumina Refractory Mortar Usage

The binder in high-alumina refractory mortar primarily promotes the adhesion of the mortar. However, the binder will disappear after high-temperature baking. Therefore, high-alumina mortar that has been stored for a long time needs to be assessed for its continued usability using the methods described above. By checking the storage condition of the binder and conducting simple tests, the feasibility of using high-alumina refractory mortar can be effectively determined, avoiding the impact of material issues on the bonding effect and construction quality of refractory bricks.