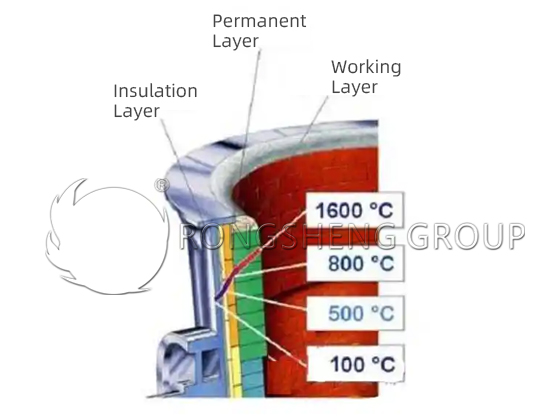

Regenerative continuous heating furnaces enable steel companies to efficiently utilize low calorific value fuels. However, compared with ordinary steel rolling heating furnaces, the combustion method, heat exchange method, heat exchange medium and other aspects of the regenerative heating furnace have undergone major changes. The furnace structure has also changed as a result, resulting in a series of problems such as more channels in the furnace wall of the regenerative heating furnace, complex structure, and difficulties in construction and baking. As a result, the airtightness and comprehensive integrity of the working lining are poor, and the refractory materials in the furnace lining and burner area are prone to cracking and damage during use.

In addition, the high-temperature flue gas and high-temperature preheated combustion medium of the regenerative heating furnace are circulated from the burner body and the working conditions are frequent switching between pairs of burners. It is easy to cause thermal shock cracks, thermal stress fatigue damage and burner nozzle deformation in the refractory materials in the furnace lining and burner area. In response to the above situation, refractory castable manufacturers have taken the following measures:

Improvement Measures for Castables Refractory for Regenerative Heating Furnaces

(1) Select high-quality high-alumina bauxite clinker with an impurity content not exceeding 2% as large aggregate. In order to prevent the raw materials from containing more impurities and producing low melting point substances during the high temperature process, the load softening temperature of the castables will be reduced. It affects the high-temperature performance of the castables, causing the burner to deform during operation and reducing its working performance.

(2) Select sintered mullite as fine aggregate and powder. The advantages of mullite include good structural structure, low creep rate, small thermal expansion, good thermal shock resistance and strong resistance to chemical erosion. Improve the linear change rate, thermal shock stability, erosion resistance and high temperature creep resistance of the castable, and increase the high temperature compressive strength of the castable.

(3) Select andalusite and kyanite as expansion materials, and use the volume expansion effect of andalusite and kyanite during the mulliteization process at high temperatures to improve the linear changes of the castable after high-temperature burning and improve the thermal shock stability of the castable. sex.

(4) Select dense corundum fine powder, α-Al2O3 micro powder, and silica micro powder as micro powder materials. While improving the density of the castable, the high melting point of α-Al2O3 is used to improve the refractoriness of the burner castable. Mullite and secondary mullite are generated by sintering powder and aggregate under high temperature conditions. While improving the line change rate of the castable, it also improves the comprehensive mechanical strength and high temperature performance of the castable.

In addition, the researchers added a small amount of Al-80 cement as a binding agent to improve the medium and low-temperature bonding strength of the castable by taking advantage of its rapid hardening, high strength, and fire resistance. Polycrystalline alumina fiber is added as reinforcing and toughening material, and explosion-proof fiber is added as explosion-proof agent to further improve the bonding strength and thermal shock stability of the castable. Sodium hexametaphosphate and FS20 are used as high-efficiency composite dispersants (water reducing agents) to improve the construction performance of castables.

Excellent Physical and Chemical Properties of Castables for Regenerative Heating Furnaces

Compared with ordinary high-aluminum castables, the improved castables have better comprehensive indicators. The change of its line after burning shows that it has micro-expansion, which can effectively prevent shrinkage cracks in the furnace lining and burner nozzle. The number of water cooling times at 1100°C reaches 25 times, which indicates that the thermal shock stability of the castable is good and can reduce thermal shock cracking of the refractory material in the burner part. The starting temperature of high-temperature load softening is greater than 1400°C, which is higher than the maximum operating temperature of the heating furnace. It can avoid the problems of furnace lining bulging and burner nozzle deformation, and delay the deterioration of burner performance.

In summary, the improved integral castable of the regenerative heating furnace lining and burner has a reasonable microstructure. It has the advantages of good medium and high-temperature sintering bonding, high mechanical strength, excellent linear change rate and thermal shock stability, and high load softening starting temperature. Moreover, the improved castable has good construction performance and its service life is more than doubled to more than 12 months under maintenance-free conditions. It effectively reduces the workload of furnace lining and burner maintenance, and reduces the consumption and maintenance costs of heating furnace castables, and repair materials.

Improvement of Furnace Body Refractory Castable Structure of Chamber Heating Furnace

Forging heating furnace is a key equipment in the forging industry. It is characterized by intermittent operation and large temperature changes. It often works under conditions such as high temperature and strong vibration, collision of loading and unloading machinery, and chemical erosion of iron oxide scale. It seriously damages the lining bricks of the furnace, shortens the service life of the furnace, and also causes the heat loss of the furnace to increase.

Application of High-Strength Refractory Castables in Reforging Heating Furnaces

High-strength refractory castables are good lining materials for forging heating furnaces, which extend the life of the furnace, reduce energy consumption, and achieve good economic results. In the design, the overall furnace structure of the chamber heating furnace was improved. The improvement steps are carried out according to the reservation of furnace top, furnace wall, furnace bottom and expansion joints.

(1) Stove top

The furnace top is a composite flat furnace top, and 48 high-aluminum hanging anchor bricks are evenly buried in the furnace top, with the brick length being 460mm. The anchor bricks and refractory castables form a whole, and the thickness of the cast layer is 300mm. The furnace top adopts a metal hanging structure, and the hanging bolts are connected to the metal hanging beams. The force of the hook is adjusted evenly to maintain the overall force and is in a free hanging state. The upper surface of the furnace roof is covered with a layer of 70mm thick refractory fiber to enhance the heat preservation performance of the furnace.

(2) Furnace wall

The furnace wall is a composite type. A δ=8mm steel plate is added around the furnace wall. A 40mm thick refractory fiber is pasted on the inside of the steel plate, and a 114mm lightweight refractory brick is built on the inside of the refractory fiber. The lining is integrally cast with high-strength refractory castables, and the thickness of the casting layer is 300mm. The burner hole is reserved during pouring, and the burnt bricks are embedded after the castable solidifies. The gap between the burner brick and the castable is filled with fine powder, and the furnace wall is poured at one time. Compared with brick furnace walls, it has good impact resistance and thermal insulation effects, reduces heat loss and saves energy.

(3) Furnace bottom

In order to improve the wear resistance of the furnace bottom, steel fiber reinforced castables are used and integrally poured into the pit surface. The working layer at the furnace bottom is 280mm thick, and 210mm thick refractory clay bricks and lightweight refractory clay bricks are laid underneath. Some clay bricks were laid in areas with lower temperatures, up to the ground level. Three flue holes are left in each room to communicate with the main flue, and the flues are all built with refractory sticky bricks.

(4) Connection between furnace top and furnace wall

The furnace wall does not bear the weight of the furnace top, and there is a 20mm gap between the two to allow the furnace wall to expand due to heat. In order to prevent the flame from escaping from the joint between the furnace wall and the furnace top, the two should overlap by at least 150mm, and clay bricks should be built on the side of the furnace top to isolate the flame. At the same time, wet clay bricks are used on top, and the gaps between the furnace top castables, refractory clay bricks and refractory fiber fillers are sealed to prevent fire escape.

(5) Expansion joints left

Leave an expansion joint at the four corners of the furnace wall, at the center of the middle partition wall, and at the joint between the partition wall and the front and rear. The width of the expansion joint is 3~4mm, and flammable corrugated board is used as the filling material. There are no expansion joints in the stove top itself. 20mm refractory fiber is laid around the working layer of the furnace top to replace the expansion joint.

(6)Construction

The construction of high-strength refractory castables is different from ordinary refractory castables. Therefore, careful construction must be carried out in accordance with relevant regulations. Before installing the formwork, install the burner, flue and furnace door membrane. Then set up the furnace wall formwork, and connect the hole membrane to the furnace wall formwork. The furnace top formwork is set up after the furnace bottom castables have a certain strength. After the support is completed, the anchor bricks are hung. The gap between the lower end of the anchor brick and the formwork is 0~5mm. The formwork support must be firm and must not be loose. High-strength refractory castables are finished materials that must be stirred evenly by a forced mixer before pouring. After the materials are put into the mixer and mixed dry for 1 minute, 6.5%~7.2% water is added, and then wet mixed for 3~4 minutes before the material is discharged. The mixture poured out from the mixer must be used within 30 minutes.

To purchase high-quality refractory castable products, please choose Rongsheng Refractory Castable Manufacturer. Our refractory products have been sold to more than 120 countries around the world, such as South Africa, Chile, Egypt, Colombia, Uzbekistan, Italy, Indonesia, Ukraine, Hungary, Spain, Kenya, Syria, Zambia, Oman, Venezuela, India, Peru, the United States, Ethiopia, etc. Moreover, our product quality is reliable and our after-sales service is guaranteed. Contact us for a free sample and quote for your refractory castables.