The main unshaped refractory materials used in blast furnaces include refractory castables, refractory spray coatings, refractory plastics, and refractory coating materials. The use of amorphous refractory materials in high-temperature industrial furnace linings can effectively extend the service life of blast furnaces and improve the overall application efficiency of the equipment. It can also effectively reduce internal wear problems caused by increased labor intensity.

Monomorphous Refractory Materials for Blast Furnaces

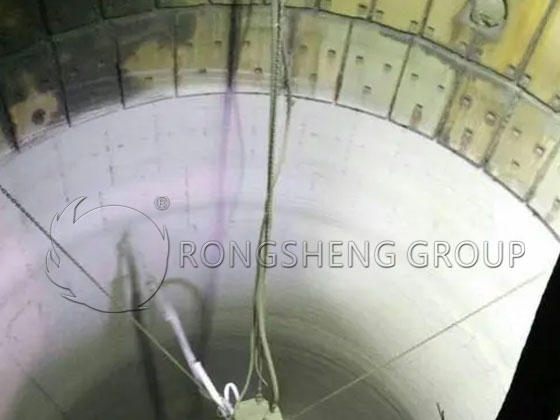

How to use unshaped refractory materials in blast furnaces, and what are the characteristics and uses of unshaped refractory materials? The development and application of amorphous refractory materials can effectively improve the construction efficiency of the furnace lining, shorten the construction period, improve the integrity of the furnace lining, and enhance the overall performance of the lining body. It can effectively help enterprises reduce the number of furnace shutdowns and furnace repairs and improve economic benefits. Rongsheng Unshaped Refractory Castable Materials Manufacturer is a professional manufacturer and seller of refractory furnace lining materials. Furnace lining solutions can be customized according to the actual working conditions of the kiln. Contact us to get free samples and quotes.

Characteristics of Unshaped Refractory Materials Commonly Used in Blast Furnaces

Compared with shaped refractory materials, the entire combustion process is canceled during the manufacturing process, which also makes the material itself amorphous. This is because the production process of amorphous refractory materials is relatively simple, and the materials are malleable. In the subsequent use process, unshaped refractory materials have the characteristics of convenient shaping. In this regard, during the casting process of the preliminary equipment, this method can be used to carry out the internal transformation of its furnace construction. This not only ensures cost reduction, but the simple manufacturing process can also increase the processing speed. It is worth noting that the service life of amorphous refractory materials is similar to that of refractory bricks, and its fire resistance and chemical stability can also reach the level of refractory bricks of the same type. Therefore, prefabrication can also be carried out before the furnace lining construction, and the unshaped refractory materials can be directly made into larger refractory precast blocks. Then, it is baked at low temperature before use, so as to ensure that it can survive long-term use inside the casting blast furnace. It can effectively extend the service life of the inner wall of the blast furnace and reduce the occurrence of internal damage caused by temperature changes.

The Use of Amorphous Refractory Materials in Blast Furnaces

- (1) When manufacturing the internal structure of a blast furnace, the brick joints are the weak links of the blast furnace brick masonry. This also makes the corrosion process mainly destroy the joints during its application. In order to ensure that the overall service life of the blast furnace is extended, the damage and damage caused by furnace lining erosion can also be reduced. When filling the brick joints, it is necessary to use refractory mud to modify them, so as to ensure that the sealing degree of the furnace lining can be improved. Since refractory mud itself is an amorphous refractory material, during the preparation process, in order to ensure the overall adhesion and refractory degree, it is necessary to identify the brick joint material of the furnace lining. And the temperature of its application effect needs to be debugged, and then its gaps must be matched. This can ensure that after the filling is completed, the blast furnace lining can completely form a smooth hole. This ensures that the overall high-temperature resistance of the lining is reduced due to erosion.

- (2) During the process of stacking the blast furnace lining, it is necessary to ensure that there is a cooling stave between the lining and the furnace shell. This kind of cooling stave requires the addition of filler so that the insulation or adhesive between the two layers of furnace lining can form its own protective film. And it can also bring out the application effect of internal substances. When a blast furnace is put into production for a period of time, the waist and lower part of the furnace body will be severely eroded due to the erosion of thermal energy. This also causes the composite energy to increase when it is working, causing the cooling equipment to be damaged under high temperatures and high pressure. At this time, bulges or cracks will appear on the surface of the furnace shell. In this regard, it is necessary to press the amorphous refractory material into the extended furnace body through the grouting method, so as to effectively increase the service life of the blast furnace. It can also reduce a series of safety risks caused by equipment damage.

- (3) When cracks appear in the blast furnace lining, the surface can be treated by gunning the lining. Under normal circumstances, a layer of unshaped refractory material needs to be sprayed at this time to prevent fission caused by cracks. At the same time, the blast furnace itself is forged with high-quality bauxite and graphite as the main raw materials. Therefore, adding a certain amount of silicide can ensure that it becomes a hard object after high pressure and high temperature. It has the functions of high-temperature resistance and good thermal conductivity. Therefore, when used, it can also effectively improve its service life.

Application Methods of Unshaped Refractory Materials in Blast Furnaces

New water wall technology

During the stacking process of the blast furnace, it is necessary to ensure that the internal cooling protection wall is formed by injection. The lining of this refractory material can also play the role of internal heat preservation and external heat insulation so that it can effectively reduce the loss of heat energy. Under normal circumstances, after one to two years of use, the internal cooling staves of a blast furnace will break. This also leaves exposed parts on the surface of the cooling stave, which increases heat energy consumption and also leads to safety hazards. Therefore, it can be said that if there is no refractory material, the slag will directly adhere to the cooling stave after combustion and cooling. Due to the large difference in its own expansion coefficient, the slag skin will fall off at any time. In order to effectively solve this problem, cermet lining can be used to transform it. Not only can it effectively protect its cooling stave, but its cermet lining can also be used to improve its fire resistance through the application of its own thermally conductive fibers, and ensure that its own metallic characteristics can be intact. This also makes it have the characteristics of better thermal conductivity and better plastic deformation ability. During application, the material will not become brittle even in high-temperature environments.

Furnace lining injection technology

Carbon monoxide inside the blast furnace will cause the deposition of carbon elements in the refractory material, which will in turn cause the overall structure of the material to be destroyed. The problems displayed on the furnace wall are internal fractures or a reduction in the strength of the material itself, or the material has cracked, resulting in irregular fractures at both ends of the material. Therefore, if it contains iron elements inside, it will catalyze this reaction, thereby increasing its overall collapse efficiency. Because, among all refractory materials, iron oxide must be used, which will react with carbon monoxide and form iron element. These iron elements happen to act as catalysts reflected in carbon deposition. Therefore, under the normal application of the blast furnace, this problem is unavoidable, which also causes the blast furnace to reduce its service life.

Nano Silica Combined with Pouring Technology

After a blast furnace has been used for several years, its taphole will show varying degrees of wear and tear, and its working efficiency will be reduced. Traditionally, when repairing it, mud cannons are used to press in to achieve overall improvement. However, this will not only increase the consumption of mud cannons, but also fail to cure the problem. In this regard, it is necessary to apply some new technologies to realize the transformation of its iron mouth. At the current stage, nano-silica combined with castable casting is one of the main application methods for taphole repair. Since silicon carbide is the main raw material, silica is used as a gelling agent, which not only effectively improves its overall structural strength, but also enables rapid drying without causing explosions. At the same time, after the repair is completed, it can also achieve an effective increase in its own structural strength.

The use of amorphous refractory materials in blast furnaces can effectively increase the service life of the furnace lining and save production costs for enterprises. Rongsheng Unshaped Refractory Materials Manufacturer, an environmentally friendly and fully automatic unshaped refractory material production line, provides a reliable guarantee for the longevity of lining materials for high-temperature industrial furnaces. Moreover, our professional technical team provides customized furnace lining materials and customized furnace lining solutions. Contact us to improve the life of your furnace lining.