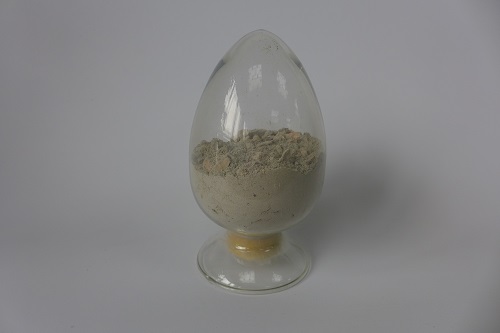

Lightweight insulation castable is the lower volume density of the castable, the basic volume density of about 1.5. The castable has many pores. Low volume density, small thermal conductivity, good insulation effect and other advantages. It is made of aluminate cement, high aluminum fine material, ceramsite, and additives.

The lightweight insulation castable good workability, strong adhesion. Strong anti- permeability, no acidizing treatment is needed, which is beneficial to ensure the compactness and fullness of the mortar seam of masonry, and can significantly improve the air tightness, integrity and anti-corrosion ability of the chimney lining.It is an ideal cementing material for lining of high chimney, high temperature flue and air duct.

This series of refractory castables has the following features:

- The heat preservation castable volume light, high compressive strength, acid and acid gas corrosion resistance, heat insulation, heat preservation, low water absorption.

- It many air holes, low volume density, small thermal conductivity, good insulation effect.

- Good workability, strong adhesion, long initial setting time and operation time.

- The strength of lightweight insulation castable increases fast, the impermeability is strong, can significantly improve the lining of air tightness, integrity and corrosion resistance.

The castable is widely used in electric power, petrochemical, metallurgy, kiln and other industries, and can also be used in non-ferrous metallurgy and other industries acid-proof pool and other acid-proof projects.

We are a professional light insulation castable manufacturer, in the production and construction of the professional technical team, rich experience, service in place, welcome to buy the needs of friends, contact us at any time.